About Meopta

Meopta is an international company with a long rich tradition of developing, manufacturing and assembling world class optical, opto-mechanical and optoelectronic products.

Meopta‘s state of the art design, engineering, manufacturing and assembly capabilities enable it to provide the highest quality products and services to the industrial, military and consumer markets.

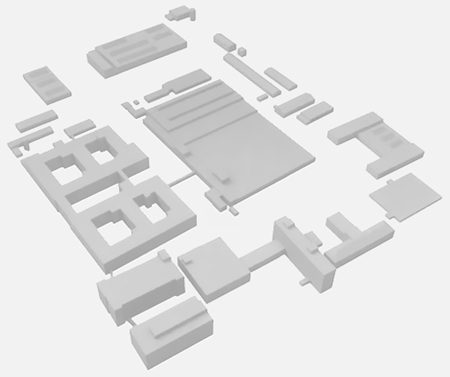

Meopta Industrial Park

1 R&D center

The Meopta R&D center is a comprehensive development department supporting engineering in the field of optics, precise mechanics, electrical, and industrial designs. Our R&D provides development, measuring and analysis of technical parameters, provides technical advisory and produces functional prototypes for internal needs and customers.

2 Optical division

The optical division is our biggest division in Meopta, where we have more than 800 optical workers and engineers. The optical division houses production of optical elements, cementing, optical contacting, vacuum coating, and other necessary production processes from block glass to finished optical components

3 Mechanics

Mechanical production is concentrated in this location, which includes dozens of latest high precision mechanical equipment. Their optimal use is ensured by more than 500 highly skilled workers and technicians. The mechanics division houses precise machining, surface finishing and heat treatment.

4 System integration

Our company is equipped with advanced assembly lines and specialized clean rooms with standard call 100 up to class 10 (US Federal Standard 209 E), where the most advanced opto-mechanical and opto-electronic assemblies are meticulously assembled.

5 Administrative offices

This building houses management and administration for all divisions and companies in Meopta Group.

Meopta’s Global Presence

Meopta - optika, s.r.o. headquarters located in Prerov, Czech Republic. This advanced state of the art facility houses R&D, Engineering, Coating Design, Manufacturing, Assembly and Administrative offices. Since 2023, Meopta - optika, s.r.o. has been part of Carlyle Group.

Does your heart beat for optics?

Meopta offers a wide range of positions with the possibility of atractive career growth. Meopta will appreciate, evolve and value your potential. High credit of our success is thanks to our people. We encourage you to reach out to our HR deparment and explain how you can help move Meopta forwards to future success.

Event calendar

IWA 2024

We would like to invite you to IWA 2024 exhibition at Nurnberg Messe, that takes place from 29th February to 3rd March. We are happy to meet you at our booth 4A-507.

Enforce Tac 2024

We would like to invite you to Enforce Tac 2024 exhibition at Nurnberg Messe, Germany, that takes place from 26th to 28th February. You can find us at booth 7A-201.

SPIE Photonics West 2024

We would like to invite you to SPIE Photonics West Exhibition + BIOS Expo, that takes place in San Francisco. You can find us at booth #8316 on SPIE BIOS Expo (27th-28th Jan). And we are also happy to meet you at booth #357 on SPIE Photonics West Exhibition…