Composite Manufacturing

Meopta has nearly a decade of experience integrating composite materials into opto-mechanical systems, with a dedicated automated composite winding manufacturing facility operational since 2024.

Composite Material Benefits:

- Major mass reduction compared to granite, aluminum, or stainless steel

- High stiffness enabled by ultra-high-modulus carbon fibers (780 GPa)

- Low thermal expansion (below 1×10⁻⁶ K⁻¹) ensuring dimensional and shape stability

Application Areas:

- Structural beams and frames for interferometers and measuring equipment

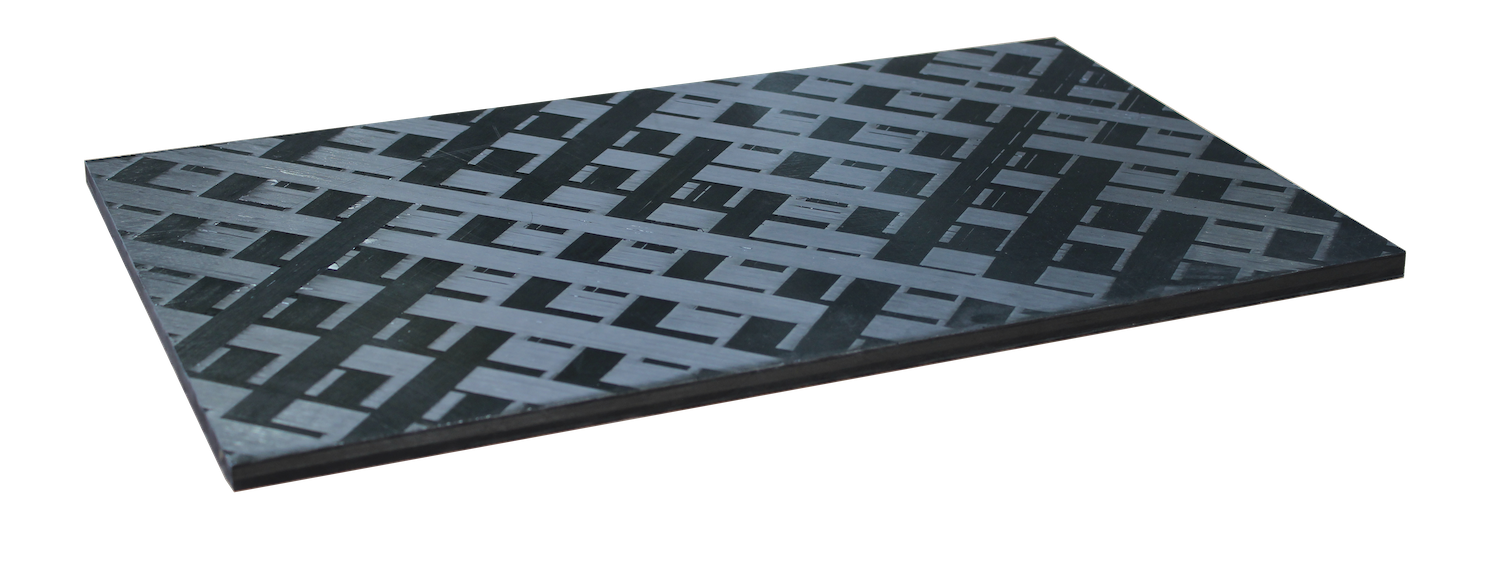

- Precision plates and breadboards for opto-mechanical assemblies

- Composite tubes for projection and inspection lenses

- Positioning systems with high precision and dynamics

Manufacturing Technologies and Equipment:

- Automated winding technology for precision composite profiles

- CNC machining of composite components

- Out-of-Autoclave (OoA) prepregs and wet lay-up technology

- Painting and surface treatments for cleanroom applications